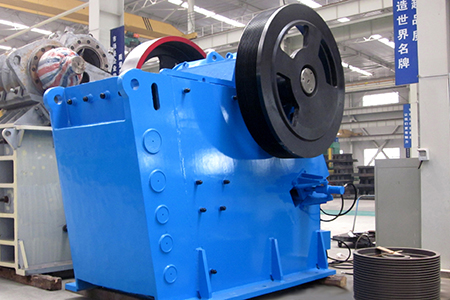

Ball mill is the key equipment for grinding materials after crushing and screening. It is also commonly used in grinding equipment. I. It is mainly used in refractory, fertilizer, cement and

This document provides guidance on ball mill grinding processes. It covers topics such as ball mill design including length to diameter ratios, percent loading, critical speed, and internals

Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide significant cost

2012年6月1日 The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills. Basic kinetic and energy

In this module, you will learn how to characterize the performance of ball mill circuits. Specifically, after completing this module, you will be able to: List and describe the four elements of the

synthesis of alloy powder. The mechanism of the ball milling process involves various techniques like impact, attrition, and compression. Various parameters that influence the alloy powder

A ball mill consists of a cylindrical steel drum (with the size of 2 to 5 m in diameter and 3 to 15 m in length) and steal balls (up to 25 cm in diameter) inside of it (see

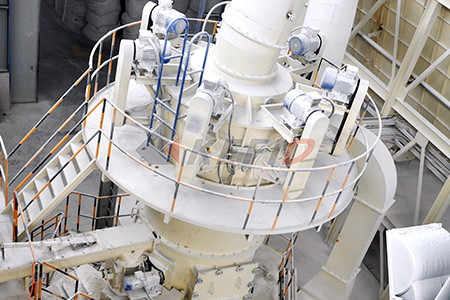

PSP Engineering has continuously refi ned the design of its ball mills. Horizontal ball mills have become a reliable part of grinding plants. Mills are driven by a circumferential drive with a

The document provides instructions for conducting an experiment using a ball mill, including diagrams of the ball mill, an explanation of how ball mills work to grind materials, factors that

Cost-effective, reliable and energy-saving: with its high-performance range of ball mills for the grinding and drying of a wide variety of materials, thyssenkrupp Industrial Solutions offers

آلیاژسازی ball من pdf > Convert JPG to PDF. Images JPG to PDF online. Convert JPG images to PDF, rotate them or set a page margin. Convert JPG to PDF online, easily and free. > AskYourPDF:

The proven classical option for cement grinding. Whether employed as a two-compartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable

2020年7月2日 PDF A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, ...

Ball Mill Grinding Process Handbook - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document provides guidance on ball mill grinding processes. It covers

The seating and drives of the mill are similar to cement mills. Assembly of a raw mill Ø 5.4 x 11 m with pre-drying chamber 3D model of a raw mill Raw mill Ø 5.4 x 11 m with a pre-drying

into the mill as recirculating material; this prevents overgrinding of the finished product in the ball mill discharge. Heat generated during the grinding process can be dispersed by good mill

کلیدواژه: مواد نانوساختار ، nanostructured materials ، آلیاژسازی مکانیکی ، mechanical alloying ، سنتز ، synthesis ، پراش پرتو ایکس. ، x ray diffraction ، عملیات حرارتی ، Heat Treatment ، آهن ، IRON ، مولیبدن ، MOLYBDENUM ، گرافیت ، graphite ، آسیاب گلولهای ، ball mill ، پودر

PDF (1.45 MB) Frequently asked questions. FAQs for ball mills. What is the ball mill used for? ... Inside a ball mill, rotating cylindrical drums are filled with grinding media (usually steel or ceramic balls). As the drum rotates, the

An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance. With

2023年4月23日 PDF Comminution is a ... In ball mill operations, it is always helpful to op timise the grinding media system to min-imize the costs of the operation. In a research done by Yu et al. [16] ...

2021年1月1日 In this paper, the design method of three chamber ball mill is introduced. Comchambered with the design of Φ 3.5 × 13m three-chamber ball mill, the design process of ball mill is described in ...

The ball mill maintenance period can be divided into 3-6 months for minor repair, 6-12 months for medium repair and 60-120 months for major repair. In the daily operation process, we should also pay attention to the ball mill maintenance. These are the basic maintenance conditions

معرفی آلیاژسازی مکانیکی به عنوان روشی مؤثر برای فرآوری ... 2- آسیاب گلولهای- ارتعاشی (Vibratory Ball Mill) 3-آسیابهای ساینده (Attritor Ball Mill) 4- آسیاب افقی غلتان (Tumbler Horizontal Mill)

یک بالمیل (Ball Mill) یا همان آسیاب گلولهای ناکارآمد علاوه بر تحمیل هزینههای بیشتر، کیفیت محصول نهایی را نیز تحت تاثیر قرار میدهد. ... پوششدهی و آلیاژسازی: ...

2015年11月30日 Ball Mill - Download as a PDF or view online for free. Ball Mill - Download as a PDF or view online for free. Submit. Ball Mill. Nov 30, 2015 Download as pptx, pdf 64 likes 51,755 views AI-enhanced description. I. ibne-obaid. The document discusses the ball mill, which is a type of grinder used to grind materials into fine powder.

The geometry of a mill with conical ends is shown in Figure 8.6. The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm (8.16) The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball mill, or large lumps of ore in an

حقوق الطبع والنشر: شركة خنان ليمينغ لتكنولوجيا الصناعة الثقيلة المحدودة. رخصة أعمال